My water pump was a complete mess and in order to remove it from the block I had to chop it to pieces due to the amount of corrosion.

Follow my project of restoring a 1965 MK II MG Midget classic car. This will be a complete rebuild restoration.

Wednesday, 28 September 2022

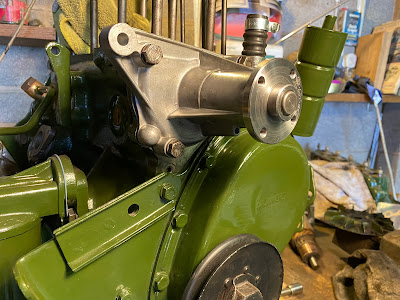

Water Pump fitting

Distributor Overhaul and Fitting

This is the only photo I have of the distributor before I took it all apart and cleaned it. All I can say was that is was covered in grease and oil.

Slightly annoyed I didn't take photos. However the lower half of the dizzy is very mechanical and there is only really one way it can be reassembled, which left the top half.

I decided not to mess around and bought new points and condenser.

Fitted the new condenser and connected up the black lead that connects the wiring from the coil.

You can now adjust the points setting using the 0.014in or 0.016in feeler gauge, by undoing the screw and pushing the points up to the feeler gauge. Then tighten the screw before removing the feeler gauge.

Fitting Engine Head

Now that the engine and gearbox was in the car I needed to attach the head.

Straight into it and need to place the new head gasket, but before you can do that you must thoroughly degrease all the surfaces and ensure there is nothing but smooth clean metal.

Plenty of suppliers to choose from but settled on one from ebay as they had speedy delivery. Big mistake!

When I first went to tighten up the nut the stud threaded.

You should now be ready to torque up all the bolts. I found that I needed to undo all the rocker adjuster bolts to make sure there was no resistance when tightening down the head.

You must refer to your engine manual to ensure you have the correct torque settings and the correct order which to tighten them, otherwise you're in danger of having to repeat this process again and having to buy a new gasket.

But here is the correct order for my 1098. The four rocker pedestal nuts are to be torqued to 25lb f ft (3.4kg f m) and the nine cylinder head nuts to 40lb f ft (5.5kg f m).

With the head in place you can now start the process of adjusting the rocker arms so they operate correctly.

You'll need a 0.012in feeler gauge to ensure the correct gaps are maintained between the values and the rocker arms.

You then have to follow the correct order as shown in the manual as shown below when setting each valve.

Turn the engine over using a suitable spanner until valve number 8 is completely open. You might need to turn the pulley backwards and forwards a few times to get it right.

Then moving on to value 1 start to adjust the rocker arm by loosening the nut (if not already) and tightening the bolt with a screw driver until the rocker arm is just touching the value.

I spent some time cleaning up the fan blades and they came out really well with nice new paint.

Really pleased how it is all coming together.