When I bought my MG Midget the prior owner included a set of bumpers that were not in a good state.

The chrome was very pitted or flaking and the mounting brackets and other steel parts were very rusty.

I thought I would be looking either a brand new set or a serious bill to restore them.

As the years ticked by I did keep an eye on auction sites to see if anything would come up. Most of the time ones that did come up where in a similar condition to mine or worse or just too expensive for second hand.

But then one day I found two adverts on eBay, one for the front and one for the rear bumper including overriders. Both adverts were for the same person. Initially they seemed in good condition and at a reasonable price.

Sadly on closer inspection the front bumper had a couple of bends in it. But the rear looked good to me and the guy was down the road from my sisters house.

So I made an offer and he accepted. My sister went to pick it up for me and got chatting. Then she called me to say he'd thrown in the front bumper for no extra cost.

When they arrived I was actually really pleased as the were in really good condition...apart from the two bends in the top edge of the front bumper.

I took a gamble and had a go at straightening them out in the vice with wooden blocks to protect the chrome from getting damaged. Thankfully I managed to mostly get the bends out.

Looking close up the overriders were pitted but from a distance they looked shinny and the metal was in very good shape. I have them all the treatments I knew, aluminium foil rolled into a ball and with water rub all over. Use very fine wire wool works wonders as well. Finished off with chrome polish and all the chrome has come up well.

Important to make sure the rubber on the overriders hasn't perished. Need to replace if it has.

On the rear of the bumpers I cleaned off all the old grim and rubbed down with an oily rag.

I remember how hard it was to take all the old fixings off. Many had rusted solid and needed to be cut with an angle grinder where possible. This is better than allowing the bolts to rotate and damage the shaped bolt holes in the bumper that are there to stop the bolt rotating.

But now time to rebuild. Rest the bumper on the overrider and place all the cup washers over the holes.

Place the bracket on top. Then insert the bolt with washers. I wouldn't tighten this up fully yet, as you will need to adjust the bumper left or right when it is on the car.

Do the same for all the other nuts and bolts.

Time to mount the bumper to the car!

Then place the rubber stoppers on the chassis bumper brackets.

Add the large washers.

Then put the bumper bracket on the chassis bracket and hold in place with one hand...

and tighten the nut on with the other.

Now this is where you need to be careful not to scratch your paint and why you shouldn't tighten all the nuts up until your absolutely sure you have the bumper in the right place.

But once you do it makes a huge difference!

The rear bumper is very similar. There are two brackets this time.

With both brackets on it is time to fit it to the car.

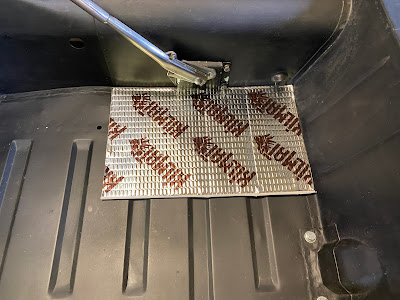

But first you need to fit the mount supports which are attached from inside the boot.

The replacement boot floor that I bought didn't have the holes predrilled for the mount, which meant I had to do it. Thankfully I did have the hole in the rear valance to help guide me.

So I needed to mark the holes out and drill away!

Hope they are in the right place.

It did take a bit longer than I thought it would to get the bolts into the bracket, but when they were all tightened up the hole in the valance also lined up. Result!

I then painted the outer bracket two tone.

and then fitted it with the chrome fittings. Looks very nice!

Ready to finish mounting the bumpers.

Access was actually quite easy when tightening it all up thankfully.

And they look really good. Not perfect but solid and perhaps one day I'll get them all fully re-chromed.

.jpg)